Pipe fitting is a critical aspect of plumbing and piping systems, involving the installation, assembly, and maintenance of piping systems used in various applications, from residential plumbing to industrial processes. Here’s a comprehensive overview of pipe fitting:

1. Pipe Fitting Basics

- Definition: Pipe fitting involves the joining and configuring of pipes and their components to create a complete piping system. This can include cutting, threading, welding, and securing pipes to ensure they function correctly within a system.

- Materials: Common materials used in pipe fitting include:

- Steel: Used for strength and durability, especially in industrial applications.

- PVC (Polyvinyl Chloride): Lightweight, resistant to corrosion, and used in residential and commercial plumbing.

- CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC but with higher temperature resistance.

- Copper: Used in residential plumbing for its resistance to corrosion and ease of installation.

- Pex (Cross-linked Polyethylene): Flexible and used in modern plumbing systems for ease of installation.

2. Types of Pipe Fittings

- Elbows: Used to change the direction of the pipe. Common angles are 45° and 90°.

- Tees: Allow for the branching of the pipe into two directions.

- Reducers: Connect pipes of different diameters, reducing or increasing the flow size.

- Couplings: Join two pieces of pipe together.

- Unions: Similar to couplings but allow for easy disconnection and reconnection of pipes.

- Flanges: Used to connect pipes to other equipment or to each other with bolts.

- Caps and Plugs: Used to close the end of a pipe or fitting.

3. Pipe Fitting Techniques

- Cutting: Pipes are cut to the required length using saws or pipe cutters.

- Threading: Pipes are threaded to allow for screw connections.

- Bending: Pipes can be bent to fit specific angles and layouts using pipe benders.

- Welding: For metal pipes, welding is used to join sections together permanently.

- Soldering: Common in copper pipe fittings, involving melting a filler metal to join pipes.

- Compression Fittings: Used to create a seal by compressing a fitting onto the pipe.

4. Installation Process

- Planning and Design: Assessing the requirements of the piping system and creating a layout that ensures efficient and safe operation.

- Measuring and Cutting: Accurately measuring and cutting pipes to fit the design specifications.

- Joining Pipes: Using appropriate fittings and techniques to assemble the piping system.

- Testing: Conducting pressure tests and inspections to ensure that the system is leak-proof and functioning correctly.

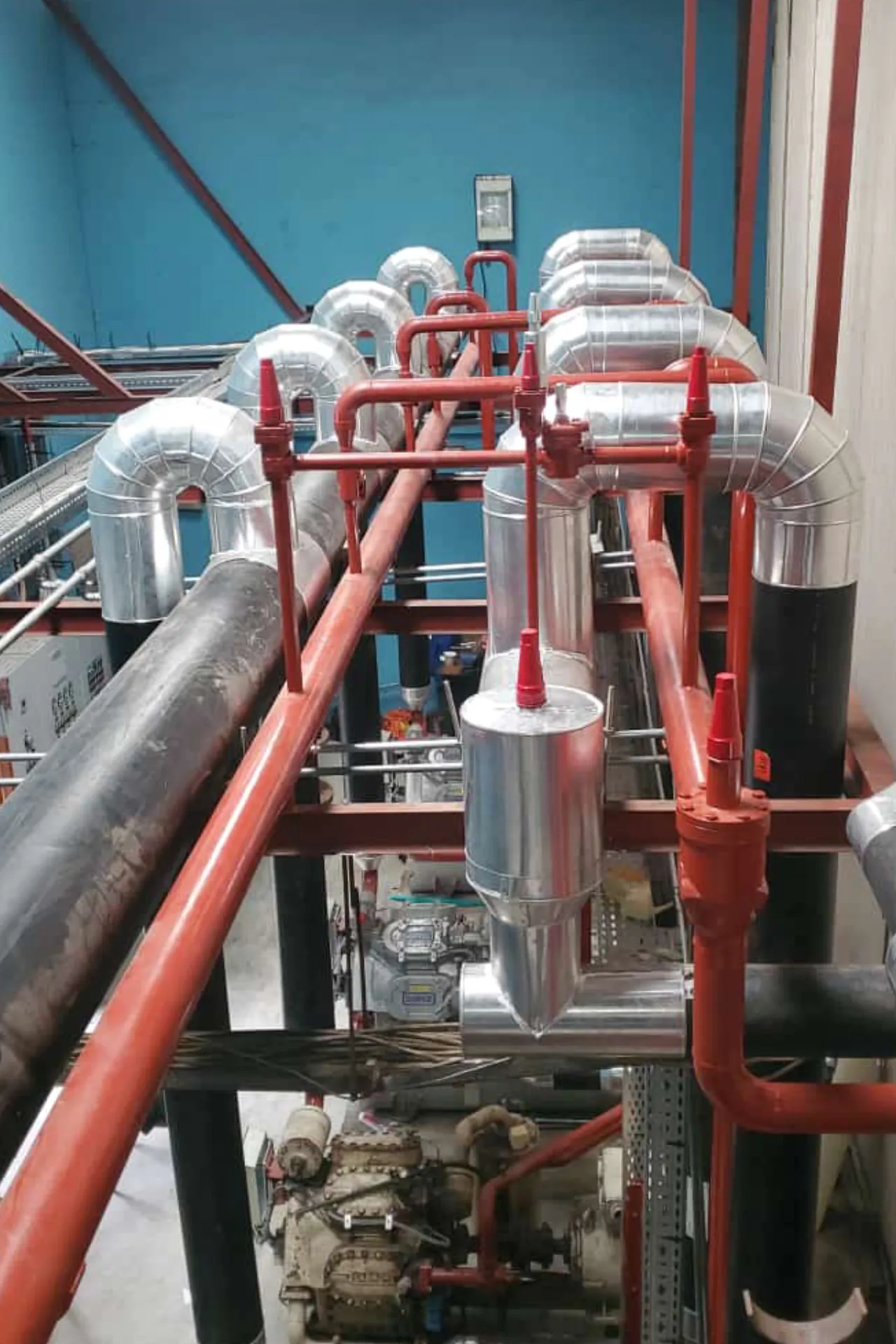

- Insulating: Adding insulation to pipes, if necessary, to protect against temperature extremes and energy loss.

5. Safety and Compliance

- Codes and Standards: Adhering to local building codes and standards, such as those from the American Society of Mechanical Engineers (ASME) or the International Plumbing Code (IPC).

- Safety Measures: Using personal protective equipment (PPE), such as gloves and safety glasses, and following safe practices when handling tools and materials.

6. Applications

- Residential Plumbing: Installation and maintenance of water supply and drainage systems in homes.

- Commercial Plumbing: Larger-scale plumbing systems for buildings such as offices, restaurants, and hotels.

- Industrial Piping: Complex piping systems in factories, refineries, and plants for transporting fluids, gases, and chemicals.

- HVAC Systems: Piping for heating, ventilation, and air conditioning systems.

7. Tools and Equipment

- Pipe Cutters: For cutting pipes to length.

- Pipe Benders: For creating curved sections of pipe.

- Threading Machines: For creating threads on metal pipes.

- Wrenches and Torque Tools: For tightening fittings and connections.

- Pipe Inspection Tools: Such as cameras and pressure testers to ensure the integrity of the system.